Moving geometry in and out of Maya can be difficult, especially moving geometry in a useable format between the two platforms. There have been attempts to move the geometry through a number of mediums, including .iges, .obj, .dwg, etc. I’ve found the majority of these to fall short in the face of highly articulated geometries. Rhino provides certain benefits over Maya, such as grasshopper and fabrication compatibility, but lacks much of the mesh control provided for in Maya.

In order to maintain the fidelity of the NURBS geometry, knowing that the geometry will be further worked in Maya, do the following:

- Select NURBS object in Rhino. Run the command : ExtractControlPolygon. Move the polygon mesh away from the original NURBS geometry.

- Export the object out of Rhino in the “wavefront OBJ” format.

- Open the object in Maya.

- Subdivide as needed. Done.

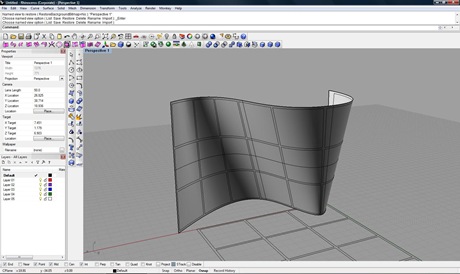

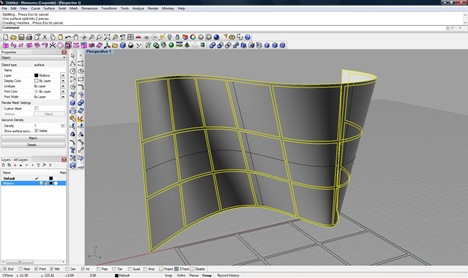

The upper screenshot below is of a surface in Rhino. The left geometry is a NURBS surface. The right geometry is the control polygon.

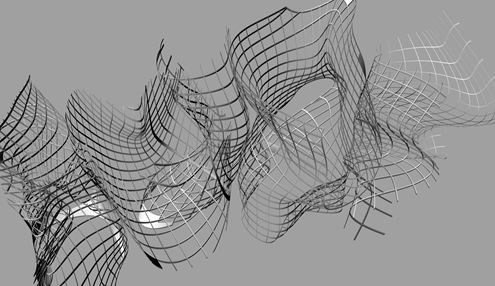

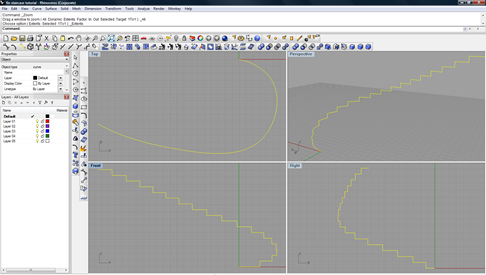

In the lower image is import geometry in Maya. The mesh on the right is the control polygon imported from Rhino. The surface on the right is a subdivided mesh straight from the control polygon (press “3” in the software…). Note that they are identical.

The only shortcoming of this method is that it only exports a single surface at a time, so if there is any mass to your NURBS model, each surface will need to be extracted and exported separately.

![[image[27].png]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEhFmEE_k7MVvpLPEC45TSPk4619-JtVs-zzo_APCsHTWrlbX1r8z5uNnl86bnxgq4GoBiFJRBxguUzy36Zbd99l9L_c8DoL8470i2UxIIvVz9KOgVM5QYM-FdtBPWUYS52p_81P6B4P7gM/s1600/image%5B27%5D.png) Just as fitting a round peg through a square hole can yield obstacles, using particle simulation software to model architectural environments can sometimes prove aggravating. I have a few criticisms:

Just as fitting a round peg through a square hole can yield obstacles, using particle simulation software to model architectural environments can sometimes prove aggravating. I have a few criticisms: